Article

Using the Elios 2 by Flyability, we have been involved in work that up until now would have been supremely costly and time-consuming, not to mention completely effective in removing the hazardous element to workers. That last part is the most important of course, but it’s also why the drone industry has been constantly evolving since its inception.

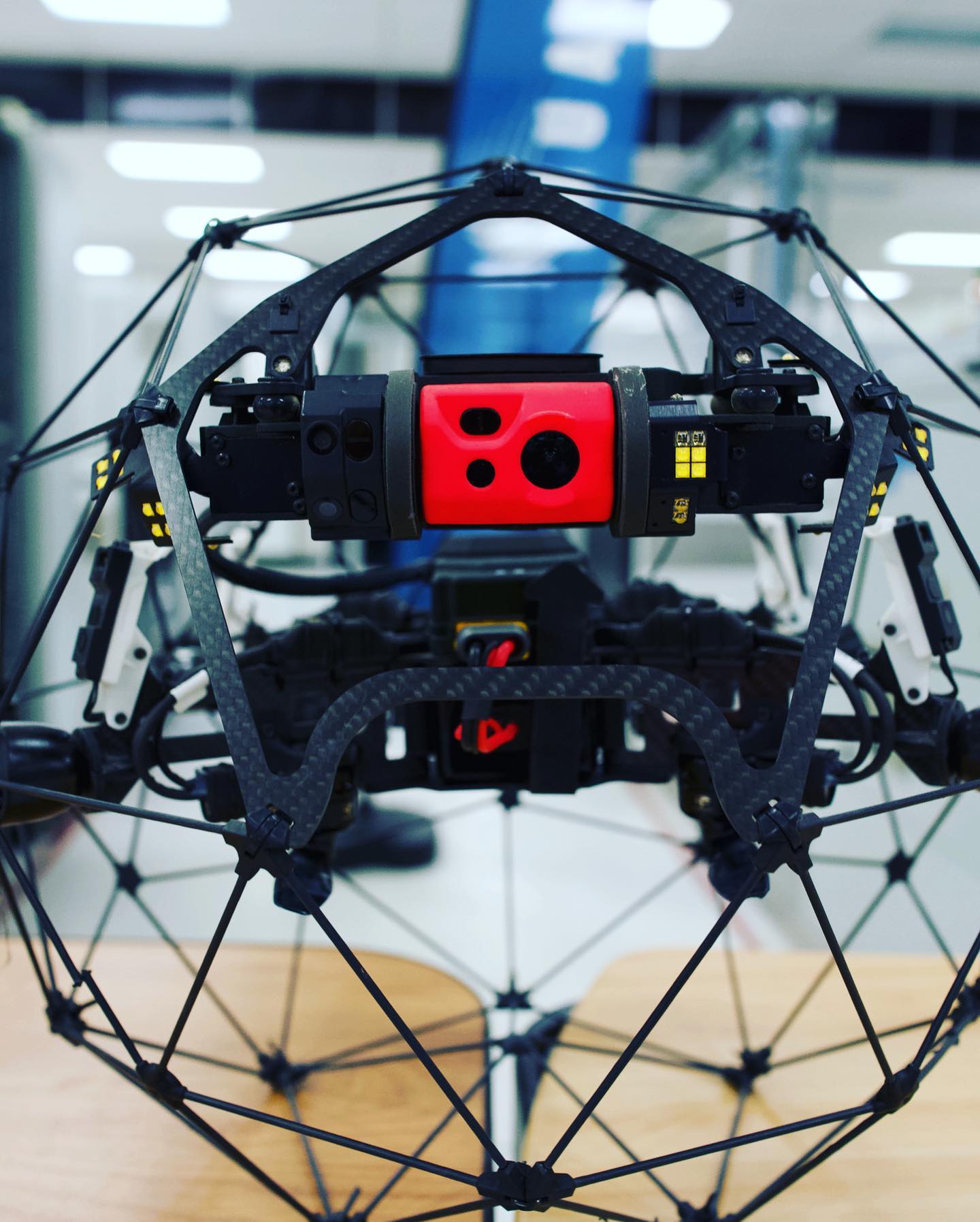

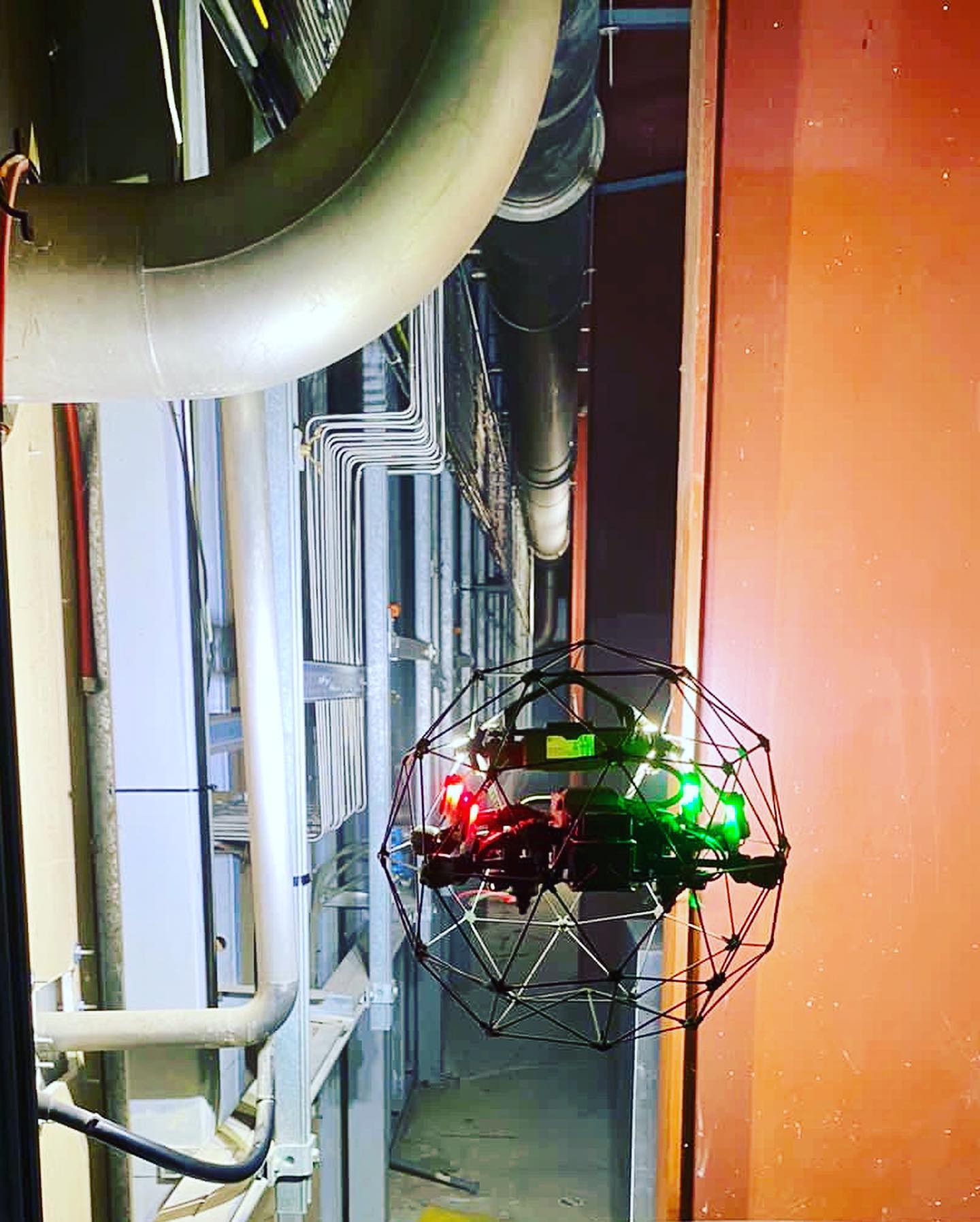

The main body of the Elios 2 aircraft is protected by a fixed flexible cage, making it perfect for internal flights, ideally into spaces and environments deemed too dangerous for workers. In that past, RUAS pilots have used the Elios 2 to fly in confined spaces such as oil tanks, furnaces and desal plant structures, to name a few.

With a powerful on-board lighting system and camera, the Elios 2 is capable of traversing internal structures and certain pipework at the hands of an experienced pilot, capturing 4K and thermal footage and still imagery throughout the flight.

One feature that is a powerful game-changer is the Elios 2’s capability in being able to create 3D models of internal spacing. By using such additional equipment like the Range Extender, the Elios 2 can keep GPS position as well as a distance lock from the structures’ surface. This in turn allows for consistent high-definition images to be taken that can be meshed into a detailed model that can aid inspection teams in identifying markers and points of interest.

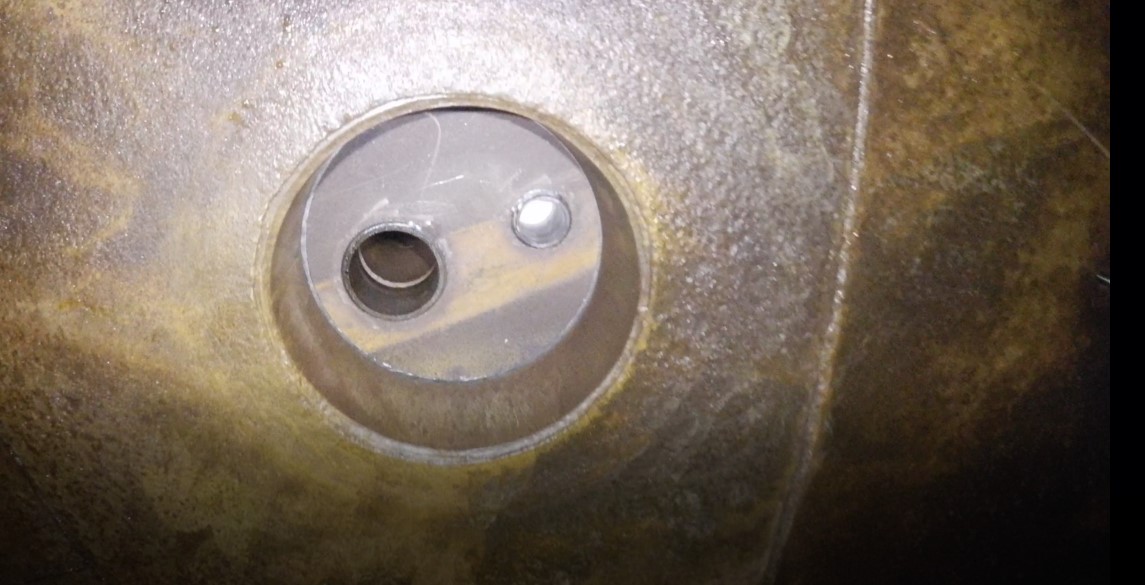

Capturing close up footage of any weeping or corrosion provides vital information that can give a great indication to a tanks’ integrity, as well as any entry points and ports. Seeing such damage before it becomes a problem is the purpose of any inspections team after all.

Through our expertise, RUAS has used the Elios aircraft in tank inspections like in the images shown here. With a professional pilot in control, this kind of operation eliminates the need for internal scaffolding and a dedicated inspections team to follow up.

Tanks such as these for example, took our experienced pilots under an hour to conduct a complete inspection for the NDT team, demonstrating how much time and cost can be saved, and more importantly, how safety for all work parties can be increased through these modern practices. Especially considering the ramifications of what empty tanks can mean for oil platforms and refineries, leaving far less time between them not being in use.

To see more about how the Elios 2 aircraft is changing internal inspeciton, visit here for more details.

Liarne Fox

January 20